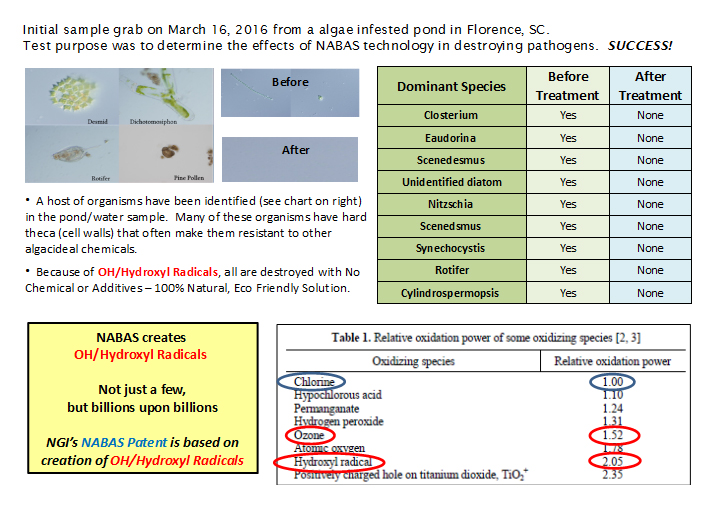

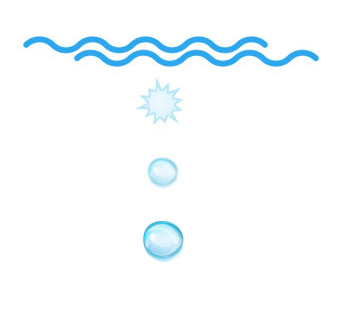

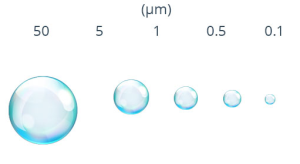

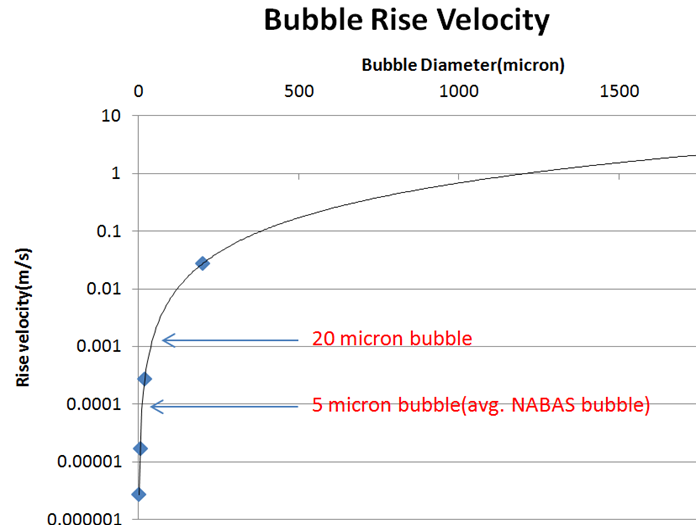

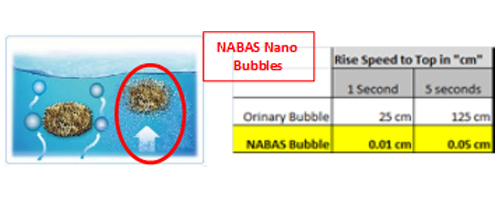

Nano Air Bubble Aeration System, or NABAS is a natural, chemical free system. The core technology centers around a gas delivery system that disperses gas bubbles and dissolves gas into a desired fluid tank or process stream. Bubbles that are 20 microns or less implode from the pressure of water, releasing the gas inside the fluid. The NABAS delivery system creates a high quantity, 80% or more, of bubbles that are an impressive 5 microns or less. These bubbles are referred to as nanobubbles; they are negatively charged, therefore attracted to contaminant particles, which then carries them to the surface for easy removal access. NABAS is able to achieve DO (dissolved oxygen) 3-4 times higher than conventional aeration products by creating enough nanobubbles to shift the fluid to be in equilibrium with the bubbles instead of the surface. Additionally, intense localized temperature and pressure from the bubble collapse generates free radicals. The most reactive and non-selective free radical produced is hydroxyl radical, which is used to degrade what is normally hard to remove organic contaminants and hard to sterilize pathogens. Hydroxyl radical is typically formed in current water treatment processes through the addition of chemicals, not generated in solution, a distinct NABAS advantage.

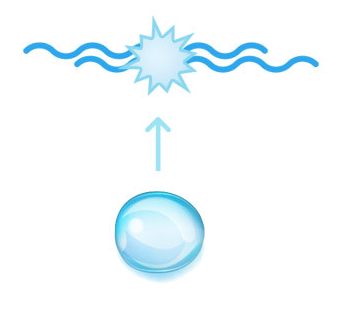

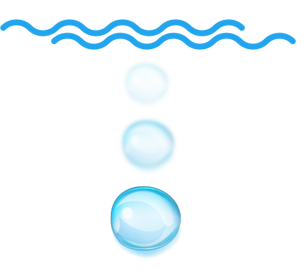

Ordinary bubbles (>20 microns)

rise and burst at the water surface

NABAS is able to achieve DO(dissolved oxygen) 3-4 times higher than conventional aeration products by creating enough nanobubbles to shift the fluid to be in equilibrium with the bubbles instead of the surface. Additionally, intense localized temperature and pressure from the bubble collapse generates free radicals. The most reactive and non-selective free radical produced is hydroxyl radical, which is used to degrade what is normally hard to remove organic contaminants and hard to sterilize pathogens. Hydroxyl radical is typically formed in current water treatment processes through the addition of chemicals, not generated in solution, a distinct NABAS advantage.

Why Nanobubbles?

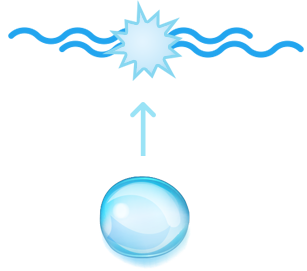

NABAS is a system that generates microbubbles that saturate the water with gas and then collapse releasing gas into the water and forming nanobubbles

NABAS Generated Nanobubbles

NABAS creates nanobubbles that remain suspended in fluid and collapse in the water, releasing oxygen and/or hydroxyl radical. Nanobubbles can attach themselves to contaminants, bringing them to the surface as suspended solids.

High Surface Area – With high surface area of the bubbles, the bubbles control the oxygen-DO relationship with the fluid.

Process Of Overview

As President Reagan once said, it is important to “trust, but verify.”

NABAS, or Nano Air Bubble Aeration System, is an internationally patented technology with U. S. Patent pending with plans to apply for patents in other countries. What makes NABAS different is:

1. Production of bubbles that measure 5μm (0.005 mm) or less; and

2. Close to 90% of production are 5μm (0.005 mm) or less

In July, 2015, Microbac Laboratories, an independent lab in Baltimore, Maryland (www.microbac.com), tested a sample of water from the Baltimore Inner Harbor using 2Hp unit, market ready models. Following EPA testing guidelines, Microbac issued a certificate of its finding. Before being treated by NABAS, the source water sample scored high on indicators of contamination and had a level of dissolved oxygen unable to sustain wildlife. Essentially, the Baltimore Inner Harbor is a dead zone that is unsafe for human contact.

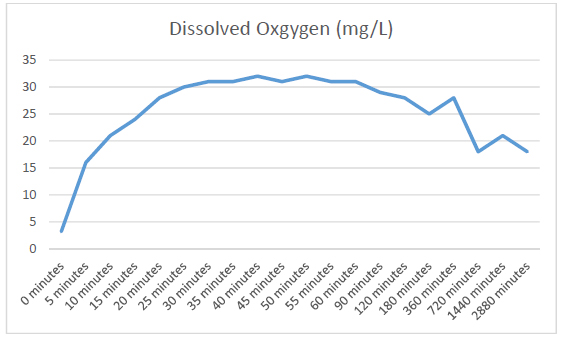

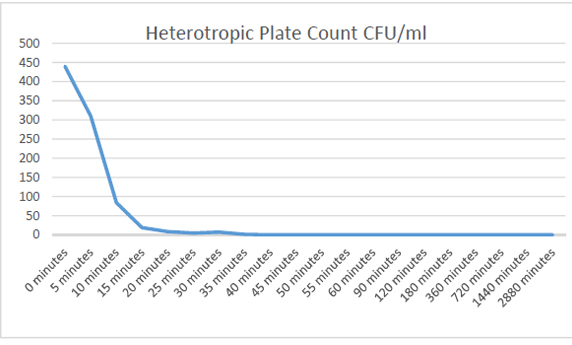

Tests were run every 5 minutes for 60 minutes to see how quickly NABAS changed the water. Within 5 minutes dissolved oxygen increased from 3.2 ppm (3.2 mg/L) to 20 ppm and continued to rise. Pre-testing, the water sample had 422 bacterial contaminant counts in 1cc (0.034 oz.) of water. Within 30 minutes the count dropped to zero. NABAS was able to achieve these results with an all natural, energy efficient process. No chemical was used.

100% Natural – Chemical Free – Eco Friendly Solution

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

NGI’s NABAS Technology: DISTINCTIONS

- 100% Natural – Chemical Free – Eco Friendly Solution (No Chlorine)

- Bubbles produced are less than 20μm (20 microns)

- More than 80% of NABAS bubbles are 5μm (5 microns) or less

- Hence Gas Absorption rate of greater than 80%

- Hydroxyl Radicals creation

- Nano Bubbles (negative charge) repel each other and saturate water

- Nano Bubbles attached to micro contaminants (positive charge) – create Suspended Solids, floating up to the water surface

NGI’s NABAS Technology: Patented Gas Delivery System in Action

Independently Verified Test Results – July, 2015

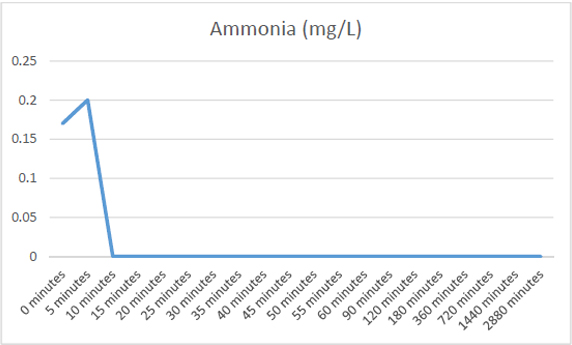

NABAS Group, Inc. (“NGI”) retained Microbac Laboratories, Inc. in Baltimore to test the efficacy of NABAS Technology. Sample: Baltimore Inner Habor water. Microbac test results below. (Complete test results available upon request.)

DO Level: 3.2 ppm to 20 ppm in 5 minutes.

HPC Count: Count of 422 to 0 (zero) in 15 minutes.

Ammonia: To 0 (zero) in 5 minutes (i.e., no odor).

No change to pH balance & other characteristics of water

~ No Chemical, just Oxygen & Ozone ~

NABAS Unit for test was: 2Hp, 20G Ozone (2015).

New “BGS” model (2016) 300% more effective.